If you are a residential, villa and remodeling customer, you are thinking more than saving money when you order durable goods from overseas manufacturers. You need to consider many factors, the whole process must be helpful for your project. How to choose a right custom kitchen cabinets manufacturer?

1. Determine your needs and meet your budget:

As a professional manufacturer, well know your requirements and preferences for your custom kitchen cabinets. Consider factors such as cabinet style, materials, finishes, storage options, and any specific design features you desire. To obtain detailed pricing information. Providing the materials the manufacturer uses for their cabinets. Quality materials, such as solid wood or high-grade plywood, contribute to the longevity and durability of your cabinets. Then offer suitable quotation to meet your budget.

If you don’t familiar with cabinet material, you can refer to What materials are commonly used in kitchen cabinets?

2. Review their portfolios, design and sample:

Look for manufacturers who provide a portfolio of their previous work or samples of their cabinets. This will give you an idea of their design aesthetics, craftsmanship, and attention to detail.

Assess whether their style aligns with your preferences and if the quality meets your standards. Customization is key when choosing a custom kitchen cabinets manufacturer.

Inquire about their ability to accommodate your specific design requests and if they provide assistance in the design process. A manufacturer with skilled designers and engineers can help bring your vision to life.

3. Updating the production frequently and do the trial assembling work before packing

Assess the manufacturer's production capacity and lead times. Ensure they can handle your project within your desired timeframe. Delays in cabinet production can cause inconvenience and disrupt your renovation schedule.

What's more. Pay attention to the responsiveness and communication style of the manufacturer. You want to work with a company that is attentive, responsive to your inquiries, and provides excellent customer service throughout the process.

The importance/necessary of doing the trial assembling work before packing:

A. Fit and Function: Trial assembling allows you to verify that the customized kitchen cabinets fit together properly and function as intended. It ensures that all the components, including cabinets, drawers, shelves, and hardware, align correctly and operate smoothly. By conducting a trial assembly, you can identify any misalignments, gaps, or functional issues before the cabinets are packed and shipped.

B. Quality Control: Trial assembling serves as a quality control measure. It allows you to inspect the materials, craftsmanship, and overall build quality of the kitchen cabinets. By physically examining the assembled cabinets, you can identify any defects, imperfections, or damages that may have occurred during manufacturing or transportation. This step helps ensure that only high-quality cabinets are packed and delivered to you.

C. Customization Accuracy: Customized kitchen cabinets are tailored to your specific requirements and design preferences. Trial assembling provides an opportunity to verify that the cabinets accurately reflect your customization instructions. You can check the dimensions, finishes, colors, styles, and other design elements to ensure that they match your expectations. If any discrepancies are found, you can address them before the final shipment.

D. Installation Validation: Trial assembling allows you to assess the ease of installation and compatibility of the kitchen cabinets with your space. By assembling them in a trial run, you can identify any installation challenges, such as incorrect measurements or incompatible features. This step helps prevent issues during the actual installation process, saving you time, effort, and potential rework.

E. Damage Prevention: During international shipping, kitchen cabinets are susceptible to damage due to handling, vibrations, and environmental factors. Trial assembling provides an opportunity to identify and address potential vulnerabilities that may lead to damage during transit. By reinforcing weak points, adding protective measures, or making packaging adjustments, you can minimize the risk of damage and ensure that the cabinets arrive in optimal condition.

In summary, conducting trial assembling work before packing customized kitchen cabinets from overseas is crucial for verifying fit and function, ensuring quality control, validating customization accuracy, assessing installation requirements, preventing damage, and ultimately achieving customer satisfaction.

It allows you to address any potential issues or discrepancies before the cabinets are shipped, resulting in a smoother and more successful project.

4. Shipment and custom

Coordinate the shipping and logistics of your import. Determine the most suitable shipping method (air freight, sea freight, or courier) based on factors such as cost, speed, and the nature of the goods.

Work closely with your supplier to ensure all necessary customs documentation is prepared accurately. This may include a commercial invoice, packing list, bill of lading or airway bill, and any applicable certificates or permits.

Provide the supplier with any required information, such as product descriptions, quantities, values, and country of origin.

5. Provide assemble suggestion and after-sale service

According to our 10 year custom cabinet manufacturer, we will provide suitable suggestion on maintain the cabinet. Regularly clean the cabinets using a mild, non-abrasive cleaner and a soft cloth or sponge. Avoid using harsh chemicals, abrasive cleaners, or rough scrub brushes that can damage the finish. Wipe away spills and splatters promptly to prevent staining or damage.

Ask the manufacturer for references from past clients in your local. Contact these references to inquire about their experience working with the manufacturer, the quality of the cabinets, and any issues they encountered. Additionally, read customer testimonials or online reviews to gather more feedback.

If possible, schedule a visit to the manufacturer's facility. Besides, there are several third-party inspection companies a third-party inspection agency designated by the customer that specialize in conducting inspections for cabinets and other furniture products. Such as SGS, TÜV SÜD, Intertek, AsiaInspection and so on.

This will give you an opportunity to see their operation firsthand, observe their production processes, and meet their team. It can provide valuable insights into their work environment, organization, and commitment to quality.

Here below the actual whole-house customized project we done in the USA:

Samples

Production

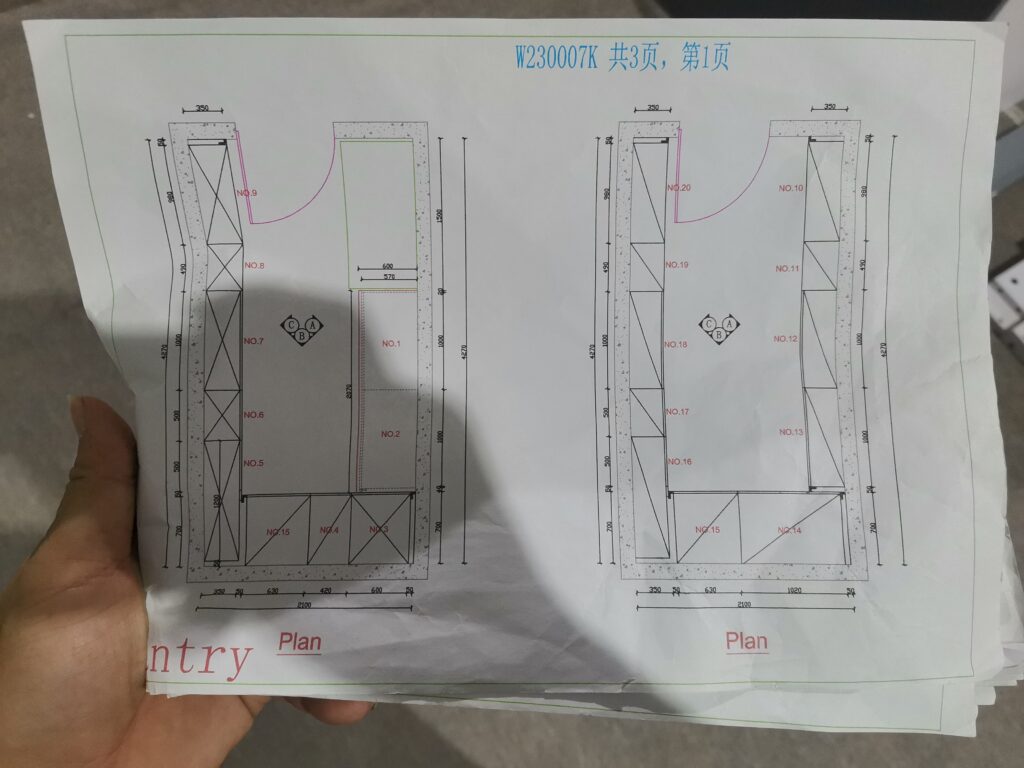

Trial assembled

Loading photos

Installation result map